Screen printing is one of the easiest types of special printing. It is used for producing business cards, posters, labels, calendars, stickers, folders, letterheads, etc. Main feature of this printing method is that you can print:

- On various materials;

- Not only on a flat surface, but also different geometrical surfaces;

- Adjusting the thickness of the paint layer, creating the effect of oil paints.

One type of screen printing is silk-screen printing that through silk mesh-based printing form can create a relief image of the reflection. If in the process of silk-screen printing, skillfully combine it with metal foil stamping or embossing, you can get high-class product.

“Vid A do Ya” Group of Companies offers silk – screen printing on plastic and fabric and manufacture and could produce for its customers:

- Business cards;

- Invitations, cards and certificates;

- Packages, posters, labels.

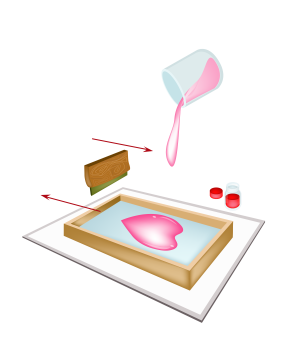

The process of getting images using screen printing consists of sequential bringing on elements casting under pressure on the printing surface, which consists of the following stages as:

- Creating a printing form;

- Complete filling it with paint;

- Extraction the form;

- Consolidation of the various options of color images.

The quality of the image element depends on the quality of printing forms, level of filling the form with the paint, conditions of the separation, which is ensuring the holding of a large amount of ink on printed elements.

The main advantages of silk – screen printing are:

- Great coating ability.

- Good relief of the paint. Lots of works printed with silk-screen printing has pretty high painted layer, you can feel by touch.

- Various special types of components and colors. Fixed color images. There are some types of paints such as: flavored, fluorescent that glow in the dark, and thermal inks